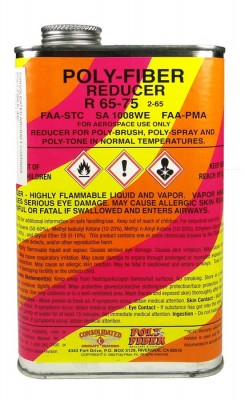

Poly-Fiber Reducer

Overview

|

A blend of solvents used for viscosity and drying control of Poly-Brush, Poly-Spray and Poly-Tone. Blend #R-65-75 is recommended as the standard reducer in normal weather, 65°75°F. #RR-8500 is a retarder-reducer with slower drying time. Recommended for temp above 85° & warm humid weather. Important Notice: All mixed paints are special order and are non-returnable. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Documents

Reviews

packaged in a non waist full size. I didnt need much and this was just right.

POLY FIBER R65-75 REDUCER QUART

Haven’t used anything yet but fast shipping

POLY FIBER R65-75 REDUCER QUART

POLY FIBER R65-75 REDUCER QUART

Keep the cap screwed down tight or it will evaporate away. Keep them in a dry place, too, as one wee rust spot and it will evaporate through that too.

POLY FIBER R65-75 REDUCER GALLON

THE REDUCER WORKS GREAT WITH THE PAINT. THANK YOU

POLY FIBER R65-75 REDUCER QUART

Very good

POLY FIBER R65-75 REDUCER GALLON

POLY FIBER RR 8500 REDUCER QUART

Work as advertised. Excellent product

POLY FIBER RR 8500 REDUCER GALLON

Used about 10% more than called for with my hvlp turbine setup. Helped the flow and results were great.

POLY FIBER R65-75 REDUCER GALLON

POLY FIBER R65-75 REDUCER GALLON

Q&A

Please note, Pilotshop.com's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Pilotshop.com assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

You would use a 3:1 Mix Ratio. 3 Poly Tone, 1 R65-75 Reducer.

FREE Shipping

FREE Shipping